Anchoring Materials

Tie-Down Engineering anchor parts and tools for mobile homes

“J” Hook Concrete Anchors are for use in wet cement and are designed to be used at the time the concrete is poured. These anchors come with a 5/8″ thick rod and a swivel head to allow for the correct alignment.

For use in existing concrete, we offer a Double Tension Head with and expansion shield. These anchors come standard with black paint, but can be ordered with a galvanized dip as is required in some locations.

Optional X Drive Anchors with attached Stabilizer are available and should be used for Soil Class 2 X Drive anchors are not approved for use in all locations. Please check with your local municipal codes before choosing your anchor. Should you need further information, call General Supply today, we will be glad to help

X Drive Anchors are perfect for use in solid rock and should be installed within 1” of the base. The correct alignment is achieved by adjusting the swivel head. These are only approved for class 1 soil conditions

Double Helix Earth Anchors are designed for clay and other hard soils. These double helix anchors are available in 30″ , 48″ and 60″ lengths.

Single Helix Earth Eye Anchors are excellent as a storage building anchor kit. These kits include 4 – 15″ single helix anchors with cable and calms

In soil conditions that may require the use of a stabilizer in addition to your double helix Anchor. General Supply offers a “Deep Set Anchor” with the stabilizer cap attached.

General Supply offers Single 6˜ Helix Eye Anchors that are ¾˜ rods and available in 36˜ and 48˜ lengths. See our catalog for further details

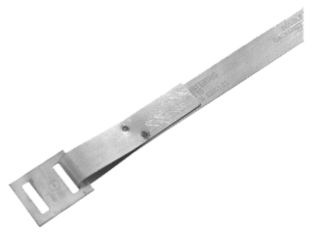

Individual strapping is also available in 37', 60' and 600' sections for people who choose to make

their own tie down straps. Strap buckles and strap hooks are sold individually along with the strap seal and crimp tool to make the job complete.

For Fast Safe and Easy Installation, General Supply offers anchor strapping in 8' and 16' lengths, with your choice of buckle or clamp for I-Beam attachment. The HUD Code requires that all strapping must meet ASTM Specifications. Strapping From Tie-Down Engineering will be properly marked every 12 inches.

Double Helix Earth Anchors are designed for clay and other hard soils. These double helix anchors are available in 30″ , 48″ and 60″ lengths.Single Helix Earth Eye Anchors are excellent as a storage building anchor kit. These kits include 4 – 15″ single helix anchors with cable and calms. In soil conditions that may require the use of a stabilizer in addition to your double helix Anchor. General Supply offers a “Deep Set Anchor” with the stabilizer cap attached. General Supply offers Single 6˜ Helix Eye Anchors that are ¾˜ rods and available in 36˜ and 48˜ lengths. See our catalog for further details

“J” Hook Concrete Anchors are for use in wet cement and are designed to be used at the time the concrete is poured. These anchors come with a 5/8″ thick rod and a swivel head to allow for the correct alignment. For use in existing concrete, we offer a Double Tension Head with and expansion shield. These anchors come standard with black paint, but can be ordered with a galvanized dip as is required in some locations.

Optional X Drive Anchors with attached Stabilizer are available and should be used for Soil Class 2 X Drive anchors are not approved for use in all locations. Please check with your local municipal codes before choosing your anchor. Should you need further information, call General Supply today, we will be glad to help

X Drive Anchors are perfect for use in solid rock and should be installed within 1” of the base. The correct alignment is achieved by adjusting the swivel head. These are only approved for class 1 soil conditions

Individual strapping is also available in 37', 60' and 600' sections for people who choose to make their own tie down straps. Strap buckles and strap hooks are sold individually along with the strap seal and crimp tool to make the job complete.

For Fast Safe and Easy Installation, General Supply offers anchor strapping in 8' and 16' lengths, with your choice of buckle or clamp for I-Beam attachment. The HUD Code requires that all strapping must meet ASTM Specifications. Strapping From Tie-Down Engineering will be properly marked every 12 inches.

|

REQUIREMENTS Installation of Concrete Bracket: Dry Set/Wet Set When LSD struts are used only as longitudinal stabilization, systems must be as evenly spaced as possible, no |

Showing 1–12 of 98 results

-

Slotted Bolt and Nut for Strapping

$1.71 Add to cart -

Pier Pad 24″ x 24″ x 1″ Black ABS 5/Bdl

$29.70 Add to cart -

Doubel Tension Head Patio Anchor Tie Down Engineering

$8.10 Add to cart -

30″ X 3/4″ Anchor Double Helix

$22.17 Add to cart -

Expansion Shield 5/8 inch x 3 inch Tie Down Engineering

$3.69 Add to cart -

Pier Pad 18″ x 18″ x 1″ Black ABS 10/Bdl

$16.50 Add to cart -

Hardwood Treated Wedges 4″ x 8″ x 1″ 30/Bdl.

$19.00 Add to cart -

24 in. Metal Pier Tie Down Engineering

$28.49 Add to cart

Showing 1–12 of 98 results